In every great structure — from the bridges that connect our cities to the high-rise towers defining our skylines — lies a silent hero: the reinforcement bar. In modern construction, Thermo-Mechanically Treated (TMT) rebars have redefined strength, resilience, and longevity. Among the pioneers driving this transformation in East Africa is Tarmal Steel, a company whose pursuit of excellence continues to shape Kenya’s infrastructure story.

Forging Kenya’s Strength

Born from a vision to build a stronger East Africa, Tarmal Steel has evolved from a single rolling mill into one of the region’s most integrated steel manufacturers, bringing together Steel Mills, Wire Mills, and Tube Mills under one umbrella.

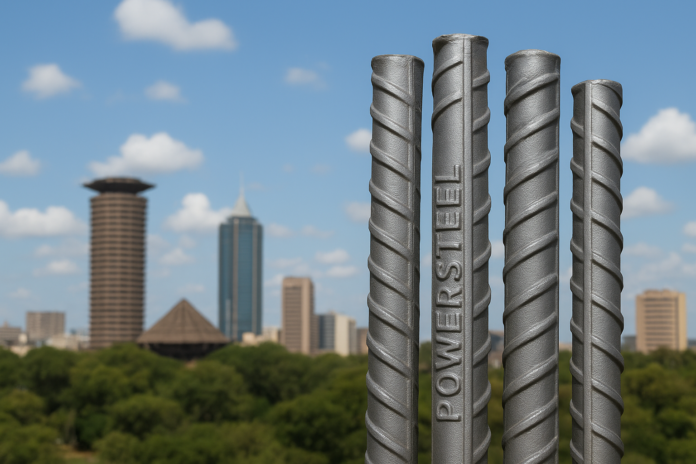

Decades ago, the company identified a crucial gap in the market — the need for consistent, high-quality reinforcement steel that could endure Africa’s demanding construction conditions, from coastal humidity to urban high-rise stresses. This quest for durability led to the birth of PowerSteel TMT Bars, engineered with world-class Thermo-Mechanical Treatment (TMT) technology.

Inside the Science: The TMT Process

What makes TMT bars stand out is their science. The process involves Quenching, where hot-rolled bars are rapidly cooled by water jets to form a hard outer layer; Self-Tempering, where heat from the core enhances elasticity and toughness; and Atmospheric Cooling, which ensures a perfect balance between strength and flexibility.

The result is a composite microstructure — a tough exterior for strength and a softer core for flexibility — enabling PowerSteel TMT Bars to perform reliably under both static and dynamic loads.

Why TMT Matters in Modern Construction

Concrete alone can withstand compression, but it’s the steel within that provides the tensile strength every structure needs. TMT bars amplify this strength further, offering three vital advantages:

- Strength and Durability

With yield strength above 500 N/mm² and superior elongation properties, TMT bars perform exceptionally under seismic and high-stress conditions. - Resistance and Longevity

Corrosion resistance up to 60% higher than conventional rebars makes them ideal for coastal or humid environments, while fire resistance up to 600°C enhances safety. - Economy and Efficiency

Their high strength-to-weight ratio reduces total steel consumption, lowering both construction and maintenance costs — a critical factor in today’s infrastructure economics.

Building Africa’s Future — One Bar at a Time

Africa’s skyline is rising fast, and with it comes the demand for materials that can stand the test of time, climate, and corrosion. From the apartments lining Mombasa’s coastline to the commercial towers of Nairobi, Tarmal Steel’s PowerSteel TMT Bars are engineered to meet these challenges head-on.

Each bar is approved and certified by KEBS, water-quenched, and marked for complete traceability — ensuring transparency and quality from mill to site.

Strength That Builds Nations

For Tarmal Steel, innovation is not just about manufacturing stronger steel — it’s about reinforcing the foundations of progress. By merging metallurgical precision with regional expertise, Tarmal is helping shape the future of construction across Africa, one bar at a time.