Last Updated 4 weeks ago by Kenya Engineer

INTRODUCTION

Determining the most effective protection for structural members, evaluating engineers discover there are numerous methods available for selection. In the early years concrete was the only material available that was suitable, consequentially it achieved the recognition as a proven material.

With improved knowledge and technology, specialized materials were developed it became obvious there was a large discrepancy in performance between traditional concrete and these new materials. The primary role of fire protection is firstly to safeguard human life and to delay the temperature rise of structural elements to minimize the consequences of fire and prevent escalation.

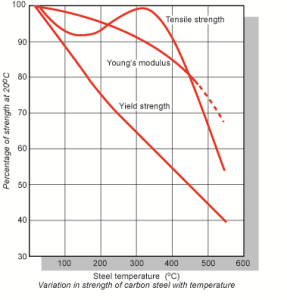

Steel members are often highly stressed to permit structural requirements to be more efficient with the minimum weight of steel. However, strength starts to decrease significantly when exposed to temperatures above 550°C resulting in possible deflection and collapse ( Fig.1) Petrochemical fires can reached temperatures of 1200°C within 3-5minutes. Where process vessels are exposed temperature rise is somewhat slower due to the internal liquid acting as a heat sink. Nevertheless, there are limits and a much higher risk of a catastrophic BLEVE,(Boiling liquid Expanding Vapour Explosion ( Ref YouTube).

Fig. 1 :Carbon steel rapidly loses strength and will deflect or collapse when temperatures increase above 550°C, petrochemical fire conditions can reach 1200°C within 3-5 minutes.

DESIGN PHILOSOPHY

Fire performance is considered in terms of three main elements.1) Thermal : relates to the properties of the fire protection material. 2) Mechanical : the relationship between steel temperature and the load bearing capacity. 3) Stickability : the ability of the fire protection material to remain in place throughout the fire period. It is imperative major load bearing members are protected so that stability is maintained until appropriate fire control measures can be taken. The length of time during a steel structure is required to maintain stability will depend on local circumstances such as type of plant, protection, and available firefighting services. Passive fire protection is one of the most effective and economic means of providing reliable fire defence. The factors that need to be considered to maintain stability :

- The type of fireproofing material and its applied thickness

- The area to mass ratio or the ratio of heated perimeter to cross-sectional area (Hp/A) of the structural member

- The applied load

- The intensity of the heat input from the fire.

- Installed systems to remain in place during a fire episode. Failure to provide an exterior weather sealer will promote corrosion beneath the fireproofing compound that will ultimately weaken the structure and reduce load bearing capacity resistance to fire.

The systems under discussion are conventional concrete, and lightweight cementitious materials. During the early 1960’s proprietary fireproofing products were introduced which showed numerous advantages over traditional concrete. Evaluation of the known data at that time concluded that the conventional systems were based on commercial and domestic fire principles as described in such standards as: ASTM E-119, AS 1530 Part 4, BS 476, ISO834, and DIN4102.

ASTM E-119 was first published in the early 1900’s, based on a standard time-temperature curve that was established from burnout tests in structures incorporating organic materials having potential heat values equivalent to wood and paper. This fire type is known as ‘Cellulosic’.

Fig. 2

Whilst conventional concrete was and is still being used, it was recognised that ASTM E- 119 and its subsequent equivalents did not adequately represent the fire conditions experienced in oil and chemical facilities. New tests were developed 1983, the USA UL Laboratories (UL1709 rapid rise hydrocarbon test) , together with a new hydrocarbon fire curve by Mobil Oil. Although these tests were not national standards at the time, they were nevertheless accepted as industry standards for hydrocarbon fire conditions.

Testing has now developed to a point where national standards are applicable and recognised, one example, British Standard BS 476 Part 20 1987 Appendix D. Lightweight cement-based materials were the first compounds to be given full certification for hydrocarbon conditions by the UK Government (Loss Prevention Council) based on this new National Standard.

Experience has shown that conventional concrete has failed and has been replaced at one time or other with specifically formulated fireproofing compounds. Lightweight cementitious materials have shown to be very effective, particularly as they can be applied off site with minimal touch-up after erection, cost is lower for example:

- The cost ratio of concrete encasement is approx. 60/100, in favour of lightweight cementitious materials.

- Possible construction delays

- Concrete starts to spall, crack, and explode at temperatures above 380°C

(Note: Hydrocarbon fire temperatures average 1200°C) steel starts to loss structural strength, deflect with possible collapse at temperatures beyond 550°C.(Fig )

- Loss of 50 % structural strength after fire -replacement can be difficult and costly.

- Fire performance is influenced by the amount of concrete cover over the reinforcing steel, limits structural design capabilities due to weight.

- Concrete density averages 2200kg/m³ compared to lightweight cementitious mixes at 800 kg/m³

- Requires considerable construction foundations with heavier steel members.

Lightweight cementitious materials provide the opportunity for:

- Design flexibility.

- Improved fire rating

- Does not spall or explode at hydrocarbon fire temperatures (i.e. 12-1600°C)

- Removes the need for replacement or in some cases no need to replace after fire.

- No form work required, therefore no waiting time for curing purposes.

- May be applied to a lesser thickness for the same fire rating.

- Economical, practically where installation to existing facilities or where access is restricted.

- Easy to maintain if accidentally damaged, does not require the use of specialised personnel or equipment.

MATERIAL DEVELOPMENT (PASSIVE SYSTEMS)

The design philosophy of these products was to limit the heat absorption and maintain a temperature within defined limits for specific emergency measures to be put into effect. The basic aim is human life protection and minimise damage to the facility.

Design Parameters

Protective systems need to conform to the following parameters:

- Limit the temperature of a structure below the maximum permitted temperature over a specified period in the stated fire condition.

- Must not fail suddenly at the end of this specified period but continue to offer a predictable measure of protection beyond this point.

- Have system integrity (stickability, integrity, and insulation) so that protection remains in place during a fire and can withstand both thermal shock and impingement of water from fire hoses or monitors.

- Be non- corrosive to the substrate and not be affected by environmental conditions.

- It must not itself become a hazard whether by spatting, spreading flame or producing toxic fumes.

- Should be easy to apply in various environmental conditions.

- The material should be durable and easily repaired.

- It must be cost effective for the risk involved.

- It should be compatible with a wide range of existing paint systems (including lead-based materials) where removal may not be applicable due to environmental or safety considerations, when upgrading existing concrete structures.

Fire Tests

Fire protection is usually provided to combat the heat input from one of the following three fire types:

A flammable liquid Pool Fire (which typically has a heat flux of approximately I20kW/m² – I50kW/m² with flame temperatures of 1000°C – 1200°C).

- An intensive torching type of impinging flame, such as may occur from a high-pressure gas or vapour leak with turbulent premixing with air from a leaking flange. This could produce a heat flux of up to 300 kW/m² with flame temperatures up to 1600°C.

- Radiant heat from an adjacent fire.

In the case of torching fires, they are smaller than pool fires, however they are more intense and can cause rapid failure where they impinge directly onto a steel structure. It is important to anticipate the points where this may occur, and fire protect those areas as a priority. Significant radiant and convective heat will also be generated from a torching flame.

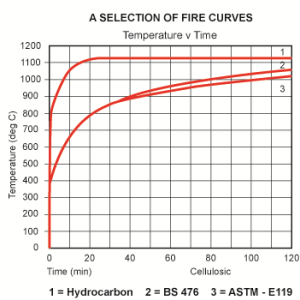

Since in practice all three conditions can occur, heat flux is difficult to measure accurately. Various fire resistance tests have been developed which are divided into two basic categories classified “Cellulosic” and “Hydrocarbon”. Both are based on a temperature/time curve (Fig 2) and do not consider heat flux. By their very nature fire tests are designed to act as a benchmark to determine, in a consistent manner the performance of structural elements exposed to a standard fire type for a pre-determined period.

Fire resistance tests provide a reproducible method by which the performance of fire protected structures may be evaluated. Failure temperatures between country’s varies slightly i.e. USA 590°C,UK 550°C,Australia 540°C. Lower temperatures means an extra conservative built in safety factor.

The name “Cellulosic” is applied to the type of temperature/time fire curve ,that is obtained when cellulosic materials or solid organic fuels such as paper or wood burn etc.

The name “Hydrocarbon” is applied to the high-rise temperature/time curve for fires where Petrochemical Products, oils, natural gas products are ignited.

TEST DATA EVALUATION

Materials are required to undergo testing by an “Independent Authority” to simulate, as closely as possible, the conditions of fire exposure to satisfy the fire endurance rating needed. Manufacturer’s in-house fire tests are not permitted or acceptable unless witnessed and acknowledged by a recognized national independent testing authority.

Standard fire tests are designed to act as a benchmark to determine the performance of products to a particular fire condition. What these tests “cannot do” is to determine the performance of:

- wind turbulence.

- thermal shock caused by water from fire hoses and/or sprinkler systems.

- Jet flame impingement.

Insulation thickness is based on either, HP/a factor (heated perimeter /cross sectional area) or Area Mass Ratio of steel. Material suppliers are required to conduct a series of independent tests minimum 9 to12 so that charts or graphs can be drawn up for a whole range of steel sections. Tests relate to load bearing members conducted for one,two,and four hours. Heat uptake is slower as thickness increases ,consequently thinner insulation is required, conversely with lighter sections thicker insulation is needed.

Bracing components receive a nominal H/Pa factor for basic cover and protection. What these tests give is a regression formular(window) on varying steel sections which defines interpolation limits for calculating the required insulation thickness. Strict limits are applied to the use of regression formular, no material thicknesses are acceptable if they fall out outside the test window. Where no regression formular is available, a single test prototype must be conducted for the steel member involved. Thickness can only be derived through INTERPOLATION (mathematics: transitive verb to estimate the value of a mathematical function that lies between known values often by means of a graph) and not EXTRAPOLATION (transitive verb to estimate a value that falls outside a range of known values).Materials should never be offered or accepted via extrapolation without the minimum test requirements.

Evidence has shown many fires last considerably longer than the designed protection period. This unpredictability has been brought into focus in many parts of the world where fires have continued for some considerable time well over the anticipated protection period.

Some materials, particularly lightweight cementitious products have been exposed to real fire where the performance has exceeded the design parameters (e.g. 1 .5-hour rating extending to over 5 hours of protection).

Fireproof material systems should satisfy the following “ minimum” test parameters:

- Standard fire test for (stickability, insulation & integrity)

- Flame impingement test where appropriate.

- Thermal shock test (from fire hoses/sprinkler systems).

When concrete comes up for consideration, its use should be discouraged, it has never been tested for hydrocarbon or even cellulosic fire resistance. The reason, it would not pass, temperature resistance is only 350-380°C. Concrete exposed to higher temperatures results in spoiling, severe cracking, major dislodgement, and has been know to loss 50% residual strength when exposed to temperatures above 350°C. Existing concrete structures can be ungraded where necessary in numerous ways, the most practical and the least expensive being the use of lightweight cementitious materials.

It is worth mentioning fire protection of concrete in the commercial building industry is mandatory throughout Australia and the Industrialized world. All high-rise buildings require protection to all structural elements, columns, beams, trusses etc, together with the underside of all concrete floor slabs throughout the building. The systems employed are mostly spray applied, lightweight materials incorporating vermiculite, in either concrete or gypsum plaster. When fire tested reinforcing steel must not exceed 250°C a much lower failure criteria than for steel members. Fire conditions under these circumstance is normally considered Cellulosic.

A rare exception was the Twin Tower buildings in 9/11, where the condition encountered was firstly hydrocarbon (1200°C), due to aviation fuel which intern ignited a cellulosic fire to the interior building components .The sheer weight of the concrete floors and deflection of the steel inward was sufficient for the building to collapse in a concertina manner.

Another classic example of concrete failure was the UK Eurotunnel fire, originally a Cementous material was proposed to protect the concrete, however this was rejected at the time of design. The future fire that evolved showed graphically the extent of damage that can occur. The estimated cost at the time was in excess $100M,six months to repair, revenue loss of $2M per day. Ironically the repair material was a Lightweight Cementous material originally recommended.

The choice of aggregate in all concrete mixtures is another important factor, river pebbles should never be used they contain water and when heat stressed explode.

CORROSION IMPLICATIONS

Fireproofing products were not designed for anti-corrosive purposes, the industry test standard to determine any corrosion properties for sprayed fire-resistant materials to steel is ASTM E93 7-83; Standard test method for corrosion of steel by sprayed fire resistive materials applied to structural members.

Where corrosion protection is necessary the use of well-designed anti- corrosive coating systems is required all of which should be based on Standards for the protection of steel.

The addition of fire cement materials is a further envelope covering the steel surface, providing a further barrier against corrosion. Cement products which show a strong alkaline reading of pH 11 plus, inhibit corrosion of steel whether it be completely bare or coated for as long as the cement remains alkaline. To emphasise this point, storage vessels which contain strong alkaline solutions require no anti corrosion treatment whatsoever.

If lightweight cement materials are used “Without” exterior waterproofing coating systems, corrosion of steel is likely to commence where airborne chloride contaminants are present and able to penetrate the material through to the steel surface, lowering the Ph. factor back to neutral or the acidic side of the scale, a process known as carbonisation of the cement component.

To ensure this situation is addressed where corrosion prevention is necessary, the following systems are recommended:

- Anti-corrosive coating system

Selection is made appropriate to each project as related to projected life and environmental conditions of exposure Systems should be selected from AS/NZS 2312 Guide to the protection of iron and steel against exterior atmosphere corrosion, or similar international standards.

- Hot Dip galvanizing (HDG)

- Zinc Rich Primer/ Epoxy sealer to 275microns minimum dry film thickness.

Of the two systems, HDG has been shown to be the most competitive with the longest case history listing of 50years plus.

In the past there has been some reluctance to the use of “lightweight cementitious” materials. This was largely due to where products had caused severe corrosion to the underlying steel. Some early formulations were based on cement, fibreglass fibre, magnesium oxychloride ,and in some cases asbestos. The use of fibre and in particular fibreglass contributes to the causes of corrosion through the phenomenon known as “wicking” whereby water together with chlorides is transported through the material to the metal surface by way of capillary action.

Whilst magnesium oxychloride provides extra hardness, they are renowned for their propensity to produce a hydrochloric acid solution which causes corrosion to steel. The use of fibre is the vehicle for transporting the acid solution to the steel surface. Fortunately, these products are now obsolete and are no longer available.

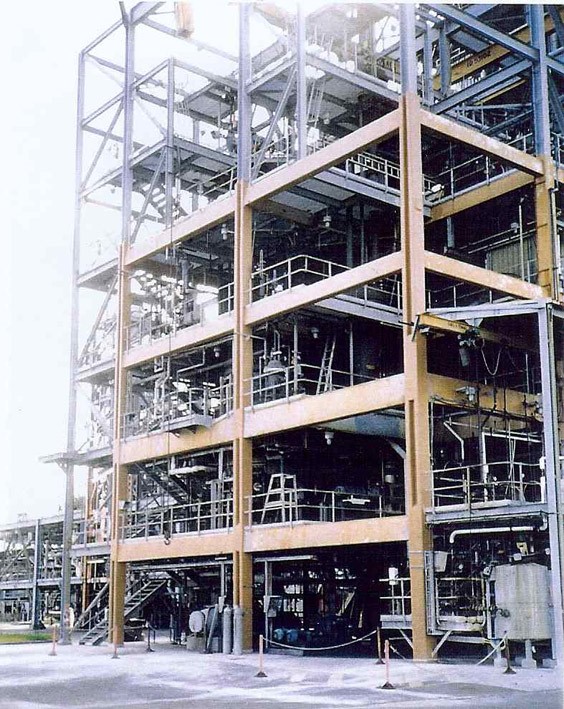

All steel sections requiring passive fire protection was undertaken with all piping, equipment, and cable trays in place. The lightweight cementitious sprayed material can be applied to provide a ‘square’ profile or a ‘contoured’ profile.

All steel sections requiring passive fire protection was undertaken with all piping, equipment, and cable trays in place. The lightweight cementitious sprayed material can be applied to provide a ‘square’ profile or a ‘contoured’ profile.

Water shedding at termination points

- Fireproofing specification (Lightweight Cementitious Material)

At the required thickness (20-50mm) includes galvanised mesh reinforcement, joint sealing and water shedding where appropriate. thickness is dependent on mass of steel involved, followed by :

Waterproofing topcoat to protect the Portland Cement component from water ingress, and carbonation, The coatings used for this purpose are either flexible Chlorinated rubber or Acrylic based applied to 250-300microns. These coatings are relatively inexpensive and require some maintenance every 12-15years.

Example of lightweight cementitious material installed retrospectively to existing, structures, when plant equipment is fully operational.

Example of lightweight cementitious material installed retrospectively to existing, structures, when plant equipment is fully operational.

Application equipment and method used comply with petrochemical “hot work permit conditions”.

HEALTH AND SAFETY

Current lightweight cementitious products are inert materials completely free of fibre materials, nontoxic, and not flammable during application or under fire conditions. Their neutrality makes them environmentally friendly and non-injurious to operational personal.

COST COMPARISON

Current estimates show that lightweight systems are quicker and easier to install with large savings, cost examples shown are based in Australian currency related to the following parameters although I would expect similar principles would apply to other international jurisdictions:

- two-hour hydrocarbon fire rating

- no allowance for scaffolding

- no water proofing or mastic sealant for conventional concrete.

There are also hidden savings when comparing to conventional concrete, steel is always on the critical Path of construction .Construction delays have a direct bearing toward plant commissioning and possible revenue loss of production. Considering the industry there is no doubt one construction delay would have a large impact on daily production values.

Requires smaller steel sections.

- Requires smaller construction foundations.

- Fewer construction delays

- Faster installation.

Economies of scale in any evaluation exercise would indicate that considerable savings can be achieved with the use of lightweight cementitious mixers without compromise to the fire protection principles.

LEGAL IMPLICATIONS

There are legal implications attached to fire protection, particulary were materials do not comply to hydrocarbon fire resistance or OH&S regulations, should any person be injured or killed. Those persons involved in the supply chain i.e. specifier, construction manager, material suppler, or installer have a shared responsibility for its performance or usefulness in the event of an untoward fire. Where deficient installation has been found, supplier and construction managers can no longer claim the responsibility was not theirs on the basis they had no control over the installation. The concept of voluntary duty of care is no longer enough, in most industrial country’s it is now a legal obligation. The use of non-compliant installation or approved materials would allow insurers the opportunity to deny liability. For individuals or corporations to ignore these issues would demonstrate a lack of responsibility, proven performance with independent test data is the only safe and secure basis for selection.

| Cost Comparison Example – 2 Hour Fire Rating | ||||||

| System | UL 1709

Approved |

UL Design

Number |

Thickness

mm |

Reinforcing

Mesh/Bars |

Density

m³ |

|

| Light weight

Cement mixture |

yes | XR704 | 36 mm | yes | 800 kg | |

| Con/Concrete | no | nil | 50 mm | yes | 2500 kg | |

| Estimated Cost per Lineal Metre | ||||||

| Steel

Section |

Lightweight

Cementitious |

Concrete Box Encasement |

Approximate Cost Savings |

|||

| 610 UB | $1350.00 | $1980.00 | 32%

35%

42% |

Direct savings, not including other.

hidden savings as outlined.

|

||

| 410 UB | $1050.00 | $1575.00 | ||||

| 250 UB | $555.00 | $960.00 | ||||

References:

UL1709 (Rapid Rise Hydrocarbon Test)

ASTME 119

ASTME 937-83

AS1530 part 4

BS476 part 20 – App D

AS/NZS 2312

Corrosion under fireproofing compounds N Karakasch.

LPG Vessel protection N Karakasch

Ref to BLEVE’s can be found on YouTube.

DGL Contractors Pty/Ltd (re costing estimates )

The Author:

Nick Karakasch is the retired principal of Total Corrosion Consultants Australia Nick’s experience spans 50 years specializing in services to the protective coating, corrosion, and fire protection industries, specializing in the areas of galvanizing, inorganic/organic zinc coatings and structural fire protection. He spent many years in a management and technical capacity with the Dimet Coating organisation. The company which invented Inorganic Zinc Silicate coatings by their founding director, Victor Nightingall now used in over 70 countries. He has also been the principal consultant to the Galvanizers Association of Australia. Whilst living in South

Africain mid-1970’s he was employed as a Contracts Manager for R.J. Southey Pty Ltd. Africa’s largest Protective Coating Contractors. Email : nkarakasch@gmail.com