Last Updated 1 month ago by Kenya Engineer

Introduction

In the construction and civil engineering sector, the lifetime and resilience of structures are paramount. Steel, a frequently used material in these projects, is susceptible to corrosion, a relentless enemy that can compromise structural integrity and necessitate costly repairs. To combat this, zinc rich paints are an excellent option, offering excellent protection against corrosion and extending the lifespan of steel structures.

What are Zinc Rich Paints?

Zinc rich paints are specialized coatings formulated with a high concentration of zinc dust or zinc flake. When applied to steel surfaces, these paints create a sacrificial layer that corrodes in place of the steel, effectively preventing rust and extending the structure’s lifespan. The magic lies in zinc’s electrochemical properties; it acts as an anode, willingly sacrificing itself to protect the steel substrate. We call this cathodic protection.

What is Zinc Flake?

Zinc flakes refer to zinc particles that are shaped as flat flakes, rather than the more common spherical or irregular shapes. These flakes are typically produced by milling or atomizing molten zinc.

Advantages of Using Zinc Flake in Zinc Rich Paints

- Enhanced Barrier Protection: The flat, overlapping structure of zinc flakes creates a denser and more impermeable barrier against moisture, oxygen, and other corrosive elements. This can lead to improved corrosion resistance compared to paints using spherical zinc particles e.g. zinc dust

- Improved Adhesion and Flexibility: Zinc flakes can provide better adhesion to the steel substrate due to their larger surface area. This can result in a more durable and long-lasting coating. Flakes can offer greater flexibility, making the coating more resistant to cracking or peeling.

- Reduced Zinc Dust: Zinc flake paints tend to produce less zinc dust during application compared to paints with spherical zinc particles.

Types of Zinc Rich Paints

Zinc rich paints are classified into two categories:

- Inorganic Zinc rich Paints: These paints utilize inorganic binders, such as silicates, to bind the zinc dust to the steel surface. They offer exceptional resistance to high temperatures, solvents, and abrasion, making them ideal for harsh environments.

- Organic Zinc rich Paints: These paints employ organic binders, such as epoxy resins, to hold the zinc dust in place. They provide excellent flexibility and impact resistance, making them suitable for structures subject to movement or vibration.

Advantages of Using Zinc rich Paints

The widespread adoption of zinc rich paint in construction and engineering projects can be attributed to their numerous advantages:

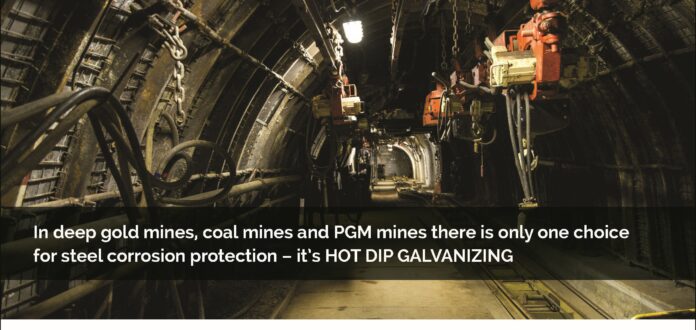

- Superior Corrosion Protection: Zinc rich paints provide unparalleled protection against corrosion, even in the most aggressive environments, such as marine or industrial settings – hot galvanizing is superior but if one cannot galvanize then use zinc rich paint

- Extended Lifespan: By preventing corrosion, these paints significantly extend the lifespan of steel structures, reducing the need for frequent repairs or replacements.

- Reduced Maintenance Costs: The long lasting protection offered by zinc rich paints translates to lower maintenance costs over the structure’s lifetime.

- Enhanced Durability: These paints enhance the durability of steel structures, making them more resistant to weathering, abrasion, and chemical exposure.

- Versatility: Zinc rich paints can be applied to a wide range of steel structures, regardless of size or complexity.

- Cost-Effectiveness: While the initial cost of zinc rich paints may be higher than conventional coatings, their long term benefits and reduced maintenance requirements make them a cost effective solution in the long run.

Applications for Zinc rich Paints

Zinc rich paints find extensive use in a variety of construction and engineering projects, including:

- Bridges: Zinc rich paints protect bridge structures from corrosion caused by exposure to the elements, salt water and moisture

- High Rise Buildings: These paints safeguard the structural steel framework of high-rise buildings from corrosion, ensuring their stability and longevity.

- Industrial Plants: Zinc rich paints shield industrial structures from harsh chemical environments, high temperatures, and abrasive conditions.

- Marine Structures: These paints protect offshore platforms, ships, and port facilities from the corrosive effects of seawater and marine atmospheres.

- Pipelines: Zinc rich paints safeguard pipelines from corrosion, preventing leaks and ensuring the safe transport of liquids or gases.

Preparation and Applying Zinc rich Paints

The effectiveness of zinc rich paints hinges on proper application. The following steps are typically involved:

- Surface Preparation: The steel surface must be thoroughly cleaned and prepared to remove any rust, scale, or other contaminants. This may involve abrasive blasting, solvent cleaning, or mechanical cleaning.

- Primer Application: A Zinc primer coat is applied to the prepared steel surface to enhance adhesion and provide additional corrosion protection.

- Zinc rich Paint Application: The zinc rich paint is applied using spray guns, brushes, or rollers, ensuring a uniform and adequate coating thickness.

- Topcoat Application: In some cases, a topcoat may be applied over the zinc rich paint to provide additional protection against weathering, abrasion, or chemical exposure.

Quality Control and Inspection

To ensure the effectiveness of zinc rich paint systems, rigorous quality control and inspection procedures are essential. These may include:

- Coating Thickness Measurement: To verify that the applied coating meets the required thickness specifications.

- Adhesion Testing: To assess the bond strength between the coating and the steel substrate.

- Visual Inspection: To detect any defects in the coating, such as pinholes, blisters, or holidays.

Zinc rich paints have improved the way we protect steel structures from corrosion if we cannot hot dip galvanize. Their ability to provide superior, long lasting protection, coupled with their versatility and cost effectiveness, has made them an indispensable tool in modern construction and engineering.

Zinc the marvel for corrosion protection of steel.

About the International Zinc Association (IZA)

The IZA is the only global industry association dedicated exclusively to the interests of zinc and its users. Operating internationally and locally in Africa through the IZA Africa Desk, the IZA helps sustain the long-term global demand for zinc and its markets by promoting such key end uses as corrosion protection for steel and zinc as essential in human health and crop nutrition. IZA’s main projects are Zinc Use Research, Sustainability & Environment, Technology & Market Development and technical Communications.

In South Africa, the IZA Africa plays a vital role in establishing the basis for the successful growth of the zinc industry by increasing awareness of zinc and its applications and benefits in key sectors and markets.